It’s a lot simpler to install an overhead service in an established neighborhood than it is to start tunneling under streets and sidewalks to run conductors underground. Overhead wires are exposed to the weather, however, and this means your service can be disrupted if a tree branch falls on it during a high wind. Modern electrical service consists of two hot conductors and one neutral conductor coming into your home. They come out of a transformer, which steps down the voltage, and must clear roofs, fences, and outside structures as they connect to your service head on top of your service mast. The conductors form a drip loop as they enter the service head so that any rain landing on them will not run down the mast.

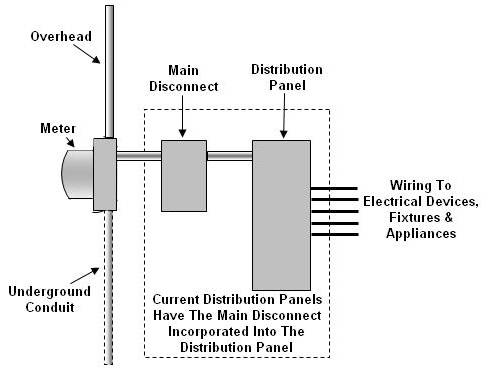

The service conductors are pulled through the mast and then pass through the meter (which records your electricity usage). Your utility connects the wires coming out of the weather head to the conductors (service lateral conductors or overhead wires) coming from the pole and the conductors to the meter, which the company usually supplies. Rules for installing an overhead service govern …

➤ The location of the meter.

➤ Clearance requirements for the conductors.

➤ Securing and supporting the service mast and raceway to your house.

Your utility company determines where the meter will be located. The company’s main concern is that the overhead conductors will be in a safe, unencumbered location. The clearance requirements for the conductors and the length of your service raceway (the mast and head) must take the following factors into account:

➤ The distance from the service mast to the utility pole

➤ The pitch of your roof

➤ Whether you’re using an IMC, PVC, or steel raceway (conduit)

➤ The proximity of windows to the proposed location

Finally, the conduit or raceway must be secured properly so it doesn’t loosen or bend. Any hole you drill for the raceway or its supports must be sealed so you don’t get water leaks. Your local electrical inspector can give you more information about clearance requirements and securing your service mast.

As you can see, this is a complicated process—and we haven’t even gotten to the service panel yet! In case you were wondering, you can’t attach any other cables (phone or TV, for example) to your service mast.

Residential electrical systems, especially newer installations or upgrades, usually just keep humming along. Cartoonists could depict billions of smiling, happy electrons zipping around our wires, one little electron holding hands with the next, doing our electrical bidding. But things can go bad. Bare wires can cross each other, appliances can short out, and lamp cords can become frayed. Your electrical system, unlike the institution of democracy, might not require constant vigilance, but you have to keep an eye on it. Circuit breakers that trip regularly and fuses that burn out too often are signs of a problem circuit. Dimming lights are a romantic touch when you control them with a dimmer switch but not when they dim on their own. Likewise, if your electric can opener shoots sparks like a Roman candle, it means you have a problem.

Residential electrical systems, especially newer installations or upgrades, usually just keep humming along. Cartoonists could depict billions of smiling, happy electrons zipping around our wires, one little electron holding hands with the next, doing our electrical bidding. But things can go bad. Bare wires can cross each other, appliances can short out, and lamp cords can become frayed. Your electrical system, unlike the institution of democracy, might not require constant vigilance, but you have to keep an eye on it. Circuit breakers that trip regularly and fuses that burn out too often are signs of a problem circuit. Dimming lights are a romantic touch when you control them with a dimmer switch but not when they dim on their own. Likewise, if your electric can opener shoots sparks like a Roman candle, it means you have a problem.

Insulation is great for maintaining your house’s temperature, but it’s terrible to pull wires through, especially the blow-in cellulose type. Worse yet is solid foam. You’ll never get a cable through that stuff. If you have insulation and you’re not inclined to pull your walls apart and remove it, consider …

Insulation is great for maintaining your house’s temperature, but it’s terrible to pull wires through, especially the blow-in cellulose type. Worse yet is solid foam. You’ll never get a cable through that stuff. If you have insulation and you’re not inclined to pull your walls apart and remove it, consider …